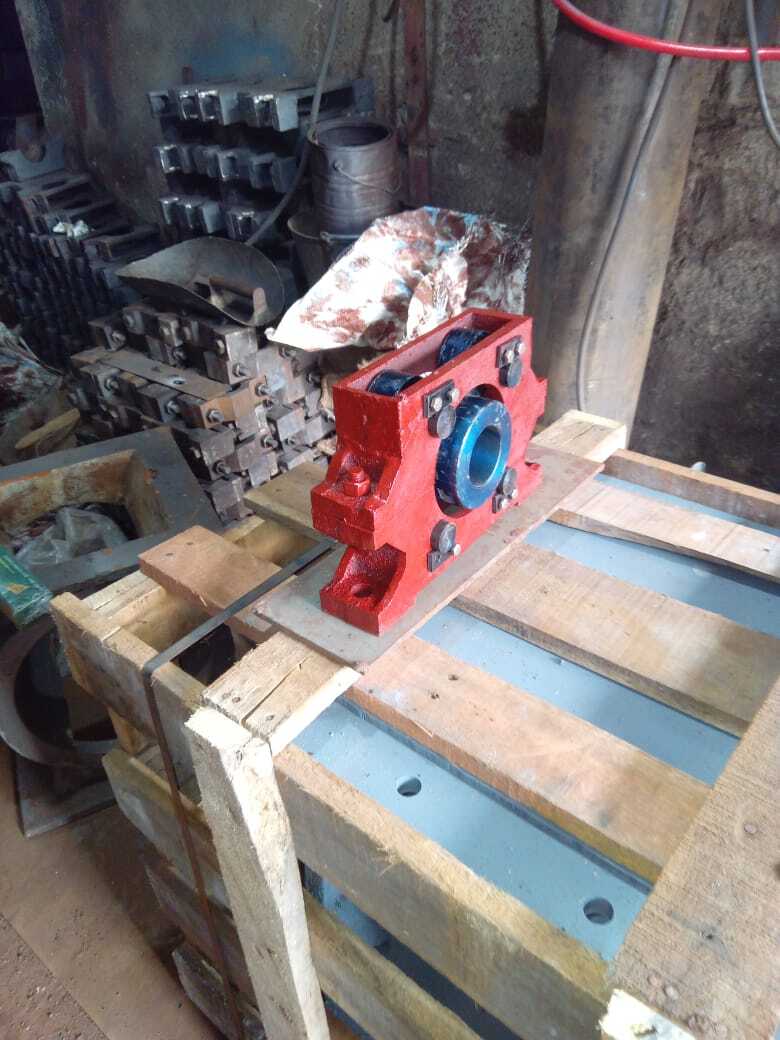

Plain Bearing For ESP Rapping System

Price 2500 INR/ Piece

Plain Bearing For ESP Rapping System Specification

- Technology

- Made using precision casting and machining technology for enhanced durability

- Accessories Type

- ESP Mechanical Spares

- Operating Pressure

- Ambient atmospheric pressure

- Automation Grade

- Manual and semi-automatic compatible

- Control System

- Mechanical control

- Machine Type

- ESP Rapping Mechanism

- Power Source

- Mechanical actuation

- Features

- Wear resistant, high load-bearing capacity, long operational life

- Surface Treatment

- Anti-corrosive surface coating

- Accuracy

- High dimensional accuracy as per industry standards

- Type

- Plain Bearing (Sleeve Type)

- Material

- High-strength alloy steel

- Function

- Supports and guides ESP shaft, enabling smooth rapping movement

- Application

- Electrostatic Precipitator (ESP) Rapping System

- Packing

- Supplied in industrial-grade cartons or wooden pallets

- Length

- Available in different lengths based on rapping system requirements

- Installation

- Easy to install and replace in ESP systems

- Temperature Range

- Operates reliably from -20°C to +200°C

- Hardness

- HRC 45-50

- Maintenance

- Low maintenance required

- Compatibility

- Suitable for various ESP models and designs

- Lubrication Requirement

- Requires periodic lubrication with mineral oil or grease

- Inner Diameter

- Customizable, typically ranges from 20mm to 100mm

- Outer Diameter

- Customizable as per ESP design

Plain Bearing For ESP Rapping System Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 1 Days

About Plain Bearing For ESP Rapping System

Swan Enterprise is a Manufacturer, Supplier, Dealer and Exporter of ESP Spare Parts from India.These ESP Internals that are used as ESP Rapping Mechanism, are our in house production. The purpose of an Electrostatic Precipitator or ESP is to avoid dust particles being expelled into the atmosphere where they can cause pollution. ESPs are installed at many types of Industrial Plant, but they are most easily identified at Thermal Power Plants , Coal- Fired Paper Mills etc.

Precision Engineering for Lasting Performance

Each plain bearing is meticulously crafted using advanced casting and machining techniques, ensuring high dimensional accuracy and consistency throughout. This guarantees a precise fit, optimal functionality, and enhanced durability during the dynamic rapping actions needed for ESP operation. The anti-corrosive surface treatment further extends the product's life in demanding industrial environments.

Versatile Customization for Your ESP Needs

Whether you require different inner or outer diameters or specific lengths, these bearings are customizable to meet unique ESP rapping system requirements. They are compatible with a variety of ESP models and designs, making them a versatile choice for manufacturers and maintenance teams alike.

FAQ's of Plain Bearing For ESP Rapping System:

Q: How do I select the correct size of plain bearing for my ESP rapping system?

A: To choose the right bearing size, determine your ESP rapping mechanism's shaft diameter and design specifications. Our plain bearings are customizable, with inner diameters typically ranging from 20mm to 100mm and can be tailored in length to suit your application's requirements.Q: What is the typical maintenance process for these plain bearings?

A: These bearings require minimal maintenance but should be periodically lubricated with mineral oil or grease to ensure smooth operation and maximize lifespan. Regular inspections for signs of wear are recommended, and replacements are straightforward due to their easy installation design.Q: When should the plain bearing be replaced in the ESP rapping system?

A: Replace the bearing if you observe unusual noise, increased shaft play, or visible wear and damage, as these can affect the rapping mechanism's performance. Regular maintenance checks will help identify the right time for replacement.Q: Where can these bearings be installed, and what is their compatibility?

A: These plain bearings are engineered for electrostatic precipitator (ESP) rapping systems and are compatible with various ESP models and designs. Their customizable dimensions enable seamless integration into different rapping mechanisms.Q: What benefits does the anti-corrosive coating offer?

A: The anti-corrosive surface coating protects the bearing from oxidation and environmental damage, significantly extending its operational life and reliability in harsh industrial conditions.Q: How are the bearings packaged for delivery?

A: For secure transport and storage, bearings are supplied in industrial-grade cartons or sturdy wooden pallets, ensuring they reach you in optimum condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in ESP Rapping Spares Category

ESP Pin Wheel

Price 2500 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Oil Extraction Plants, ESP (Expeller) Machines

Surface Treatment : Polished

Accuracy : High Precision

Material : High Grade Steel

Big Pin Wheel for ESP

Price 6500 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Industrial Dust Collection Systems

Surface Treatment : Galvanized

Accuracy : High

Material : Alloy Steel

Inner Arm For ESP Rapping System

Price 235 INR / Piece

Minimum Order Quantity : 100 Pieces

Application : Electrostatic Precipitator (ESP) Systems

Surface Treatment : Galvanized/Anticorrosive Coating

Accuracy : High tolerance alignment

Material : GI/MS (Galvanized Iron/Mild Steel)

Three Wheel with Bush

Price 800 INR / Piece

Minimum Order Quantity : 50 Pieces

Application : Industrial Automation, Material Handling Equipment

Surface Treatment : Powder Coated

Accuracy : High Precision

Material : Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS